AM Test of ASHRAE 110-2016

Date: 2022-01-18 Source: RUANQI Classification: Resources

1 Overview

Fume hood is an important equipment to control pollutants in laboratory. With the development of industry, people pay more attention to the safety and health of laboratory personnel, and the requirements for Laboratory environmental control are higher and higher. More and more countries and organizations have formulated corresponding fume hood standards. For example, the United States formulated ASHRAE 110-1995 in 1995; Europe developed en 14175 in 2013; China formulated JB / T 6412-1999 standard in 1999.

ASHRAE 110 is one of the most popular performance test standards for fume hoods in the world (another popular one is en 14175).

The world map describes the distribution of fume hood test methods [1]

ASHRAE 110-2016 describes three types of tests: am (as manufactured), AI (as installed) and Au (as used). Am is the performance test of fume hood in the factory, which is mainly completed in the laboratory under specific conditions; AI refers to the performance test of the fume hood under no-load after installation; Au is the user's performance test in use.

2 Purpose of AM test

The AM test is completed in a test laboratory with near perfect conditions. The purpose of this test is to allow users or buyers to compare fume hoods from different suppliers. By comparing the tests of each supplier, you can see the design of the fume hood and its performance compared with other facilities. You can also compare the energy costs of using a fume hood.

But this test will never show how the fume hood will work in your laboratory. It just tells you how it will behave compared with others under perfect conditions. However, because your laboratory is much more complex than the test laboratory, you will face many factors affecting performance. Each laboratory has a different laboratory ventilation system, which can also have a significant impact on performance.

Chipalbright is doing an AM test

Therefore, the usefulness of this test is to determine the design quality of the fume hood, not the performance in the actual laboratory.

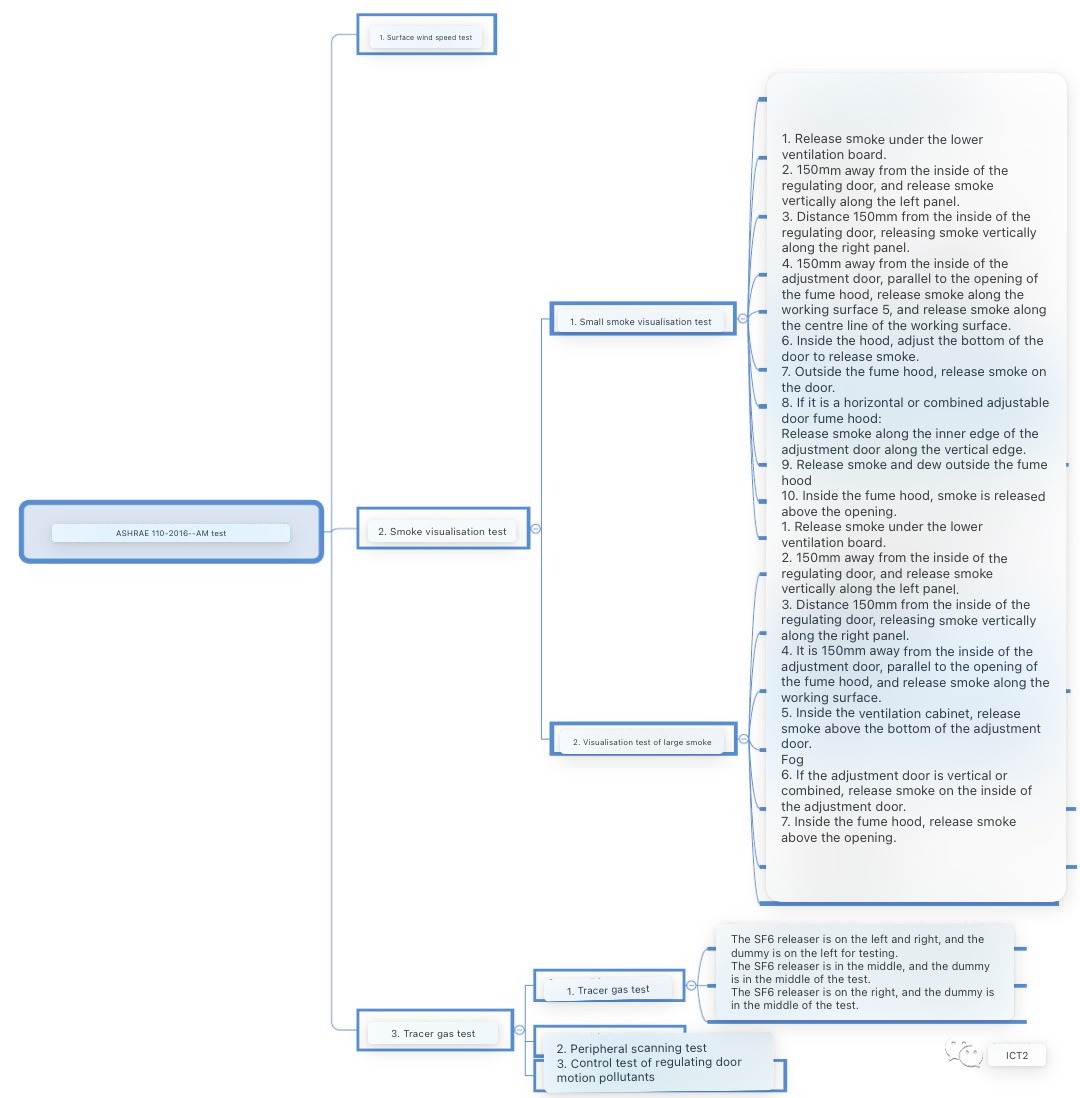

According to ASHRAE 110-2016 standard, am test includes three types of tests: surface wind speed test, smoke visualization test and tracer gas test. The following figure is an overview of am testing.

Overview of AM test methods

1) Surface wind speed test

The so-called surface wind speed is the control wind speed on the operation surface of the fume hood. As a performance evaluation index, the test method of surface wind speed has been recognized by the fume hood industry.

American National Standards Institute (ANSI) and American Industrial Hygiene Association (AIHA) formulated ANSI / aihaz9 in 1992 5-1992 laboratory ventilation standard emphasizes that the surface wind speed is an important index to evaluate the performance of exhaust fume hood. Generally, the surface wind speed shall be controlled in the range of 0.4 ~ 0.6m/s. Generally speaking, the surface wind speed is too small, which may lead to insufficient pollutant control effect on the operation surface, and the pollutants in the cabinet are easy to overflow; If the surface wind speed is too high, turbulence is likely to occur at the entrance and corner of the operation surface, resulting in pollutant overflow. The ideal surface wind speed test results should make the surface wind speed within the predetermined range and the wind speed distribution on the operating surface as uniform as possible [2].

The surface wind speed of fume hood is closely related to laboratory energy consumption. At present, according to the development situation, the fume hood will develop towards low energy consumption, such as Waldner in Germany, which reduces energy consumption by reducing surface wind speed and exhaust air volume; Some rely on world technology to take air supplement in the cabinet to reduce the consumption of fresh air in the room. The low surface wind speed fume hood has brought some disputes to the industry, but according to the statistical analysis of the manufacturer, the benefit of low surface wind speed is to save energy consumption to a great extent.

ASHRAE 110-2016 stipulates that the inlet surface of the fume hood shall be divided into equal rectangular small blocks, with an area of no more than 1 square foot (0.09 square meter) and a side length of no more than 12 inches (330mm). The acquisition point of anemometer sensor is the center of this small square.

In the actual test process, we use more professional software to assist in completing the test. By inputting the width and height of the opening surface, the software automatically generates some columns of test coordinates.

This screenshot comes from ASHRAE 110 performance test software - ALC collegedale

Then label the edge of the fume hood according to the coordinate points.

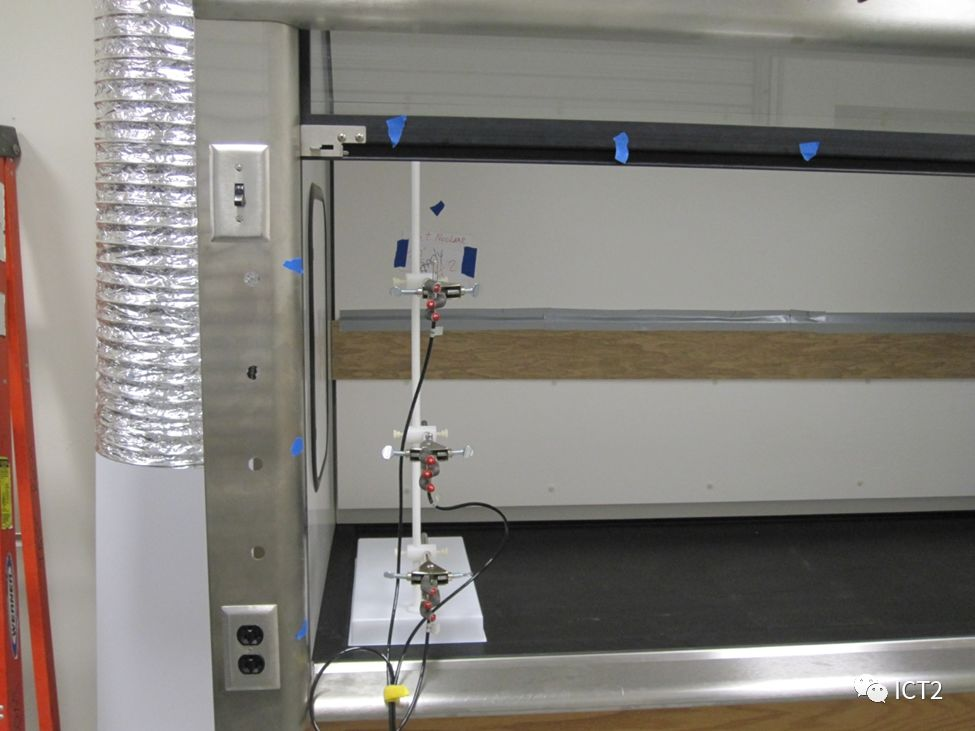

Install the anemometer sensor on the fixed support according to the position given by the software

The anemometer sensor is installed on the fixed support. One advantage of this is that the wind speed values of multiple vertical points can be collected at the same time, and the collection points are stable.

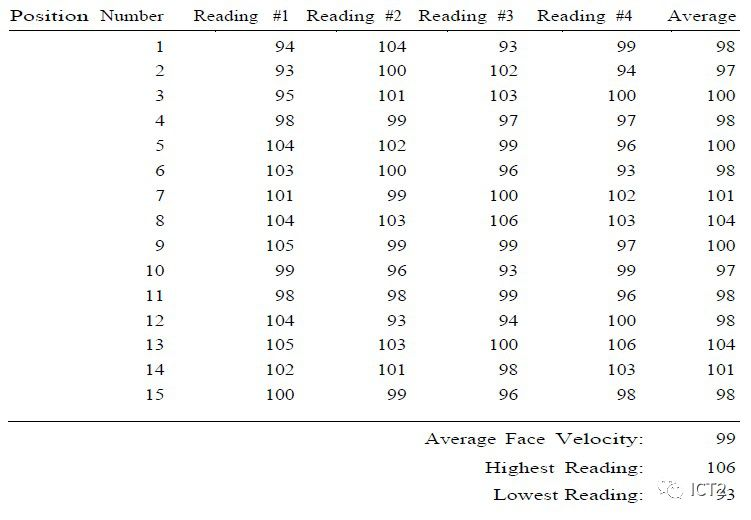

Read the readings of sensors in these squares through software, and finally get the following results:

This screenshot comes from ASHRAE 110 performance test software - ALC collegedale

2) Smoke visualization test

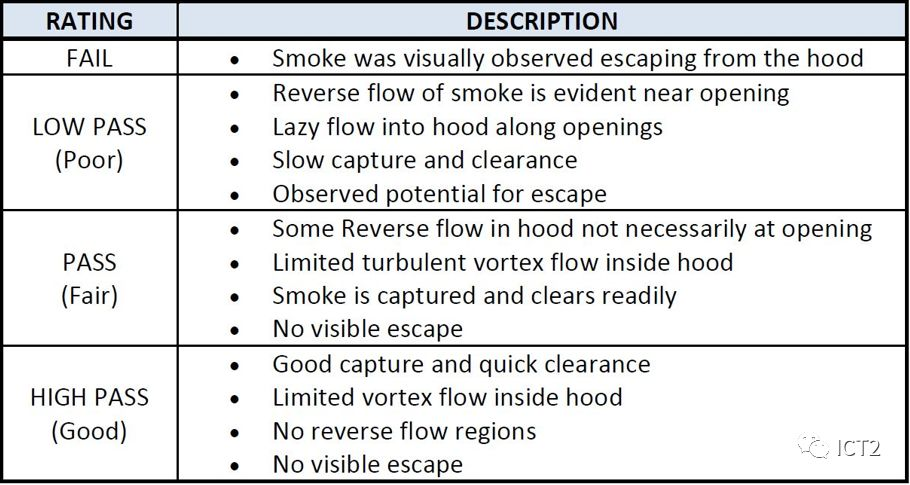

Smoke visualization uses visible smoke to display the movement form of air flow in the fume hood and whether there is smoke overflow. Ashrae110-2016 contains two tests: small smoke visualization test and large smoke visualization test. The smoke visualization test method has the advantages of simple operation and intuitive results, but the tester has strong subjectivity in the test process. In order to make the smoke test results more referential, we can make a quantitative evaluation of the smoke test artificially. The following table:

Quantitative evaluation of smoke test

*This assessment form was provided by Mr. chip Albright

A. Small smoke test

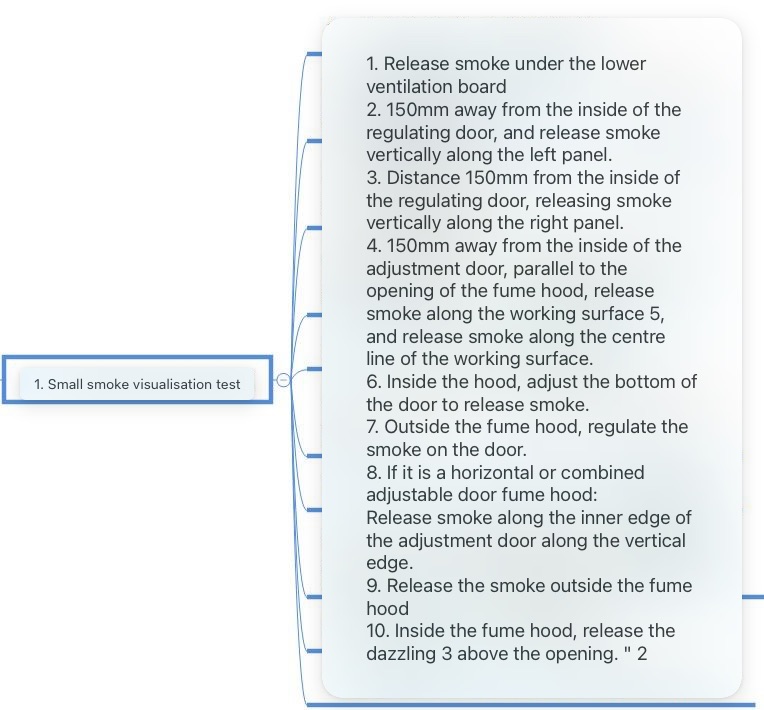

In ASHRAE 110-2016, the small smoke test includes 10 small tests, which mainly detect the gas flow pattern and overflow inside and outside the lower ventilation panel, working face, left and right panels, deflector, regulating door and fume hood. The detailed test is shown in the figure below:

10 small smoke tests

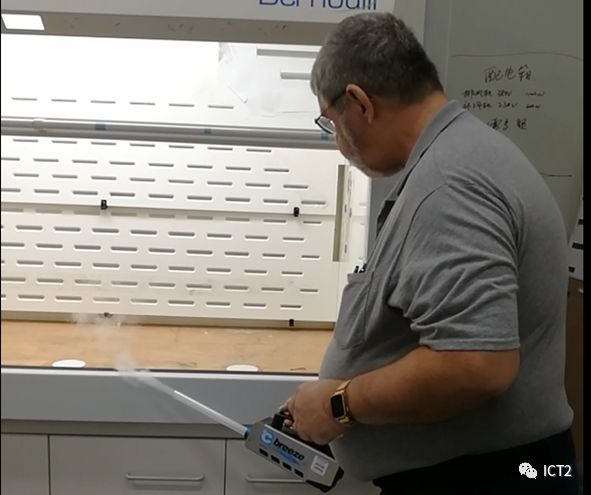

The following small series arranges some pictures of AM test smoke test, which is only for readers to learn and understand. The pictures are from the test photos of our team members in the test laboratory. If you reprint them, please get our approval.

Small smoke test of lower ventilation panel

Small smoke test on working face and left and right panels

Smoke test in the middle of working face

The above is part of the test pictures of small smoke. According to the above description, 10 small tests are the complete am small smoke test.

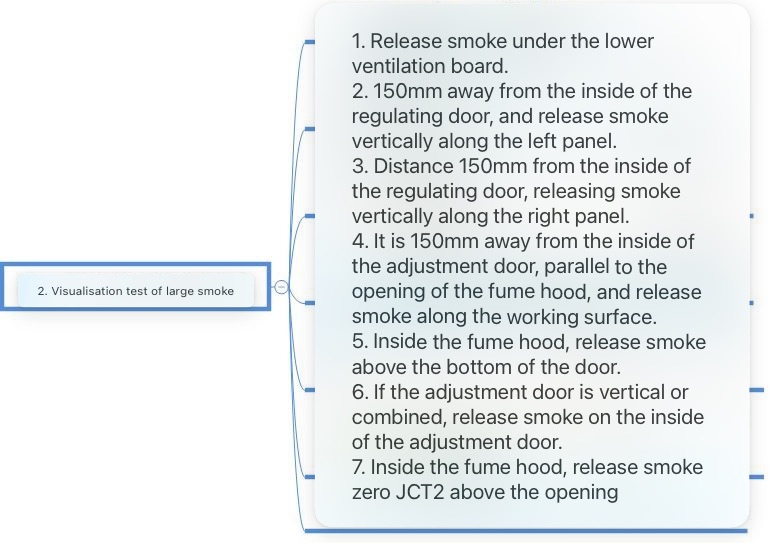

B. Large smoke test

In ASHRAE 110-2016, the large smoke test includes 7 small tests, which mainly detect the gas flow pattern and overflow in the lower ventilation panel, working face, left and right panels, deflector and fume hood. The detailed test is shown in the figure below:

7 big smoke tests

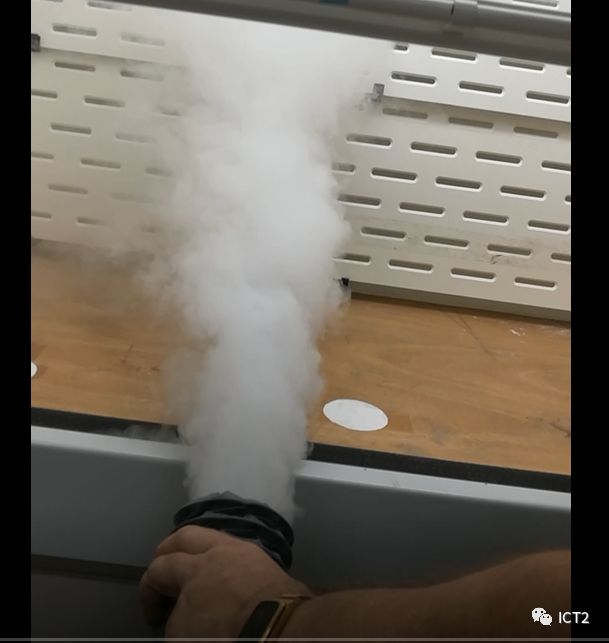

The following small series arranges some pictures of AM test and smoke test, which are only for readers to learn and understand. The pictures are from the test photos of our team members in the test laboratory. If you reprint them, please get our approval.

Large smoke test of lower ventilation panel

Large smoke test on working face and left and right panels

Large smoke test above the opening of the regulating door in the fume hood

The above is part of the test pictures of small smoke. According to the above description, 7 tests are complete am large smoke test.

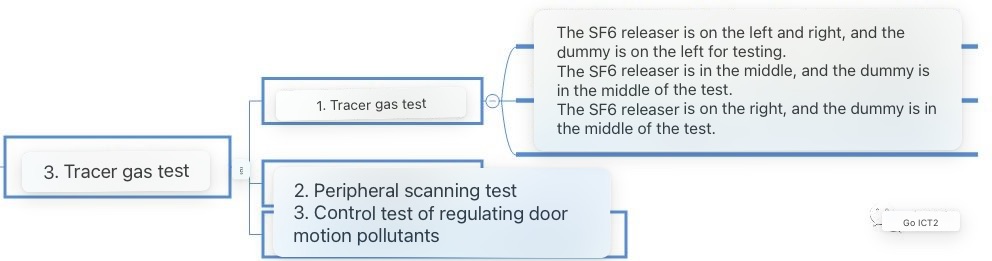

3. Tracer gas test

Tracer gas test is the most important part of ASHRAE 110 test method. It can more objectively evaluate the performance of fume hood pollutant control. Tracer gas test includes three tests: tracer gas test (left, middle and right), peripheral scanning test and regulating door switch test.

SF6 tracer gas test

ASHRAE 110-2016 has made detailed provisions on tracer gas test:

[tracer gas]

SF6 or other gases with similar and stable molecular weight are used, and the tracer gas concentration is greater than 99%. The release rate of tracer gas is 4.0 LPM (67 ml / s) at 30 psig;

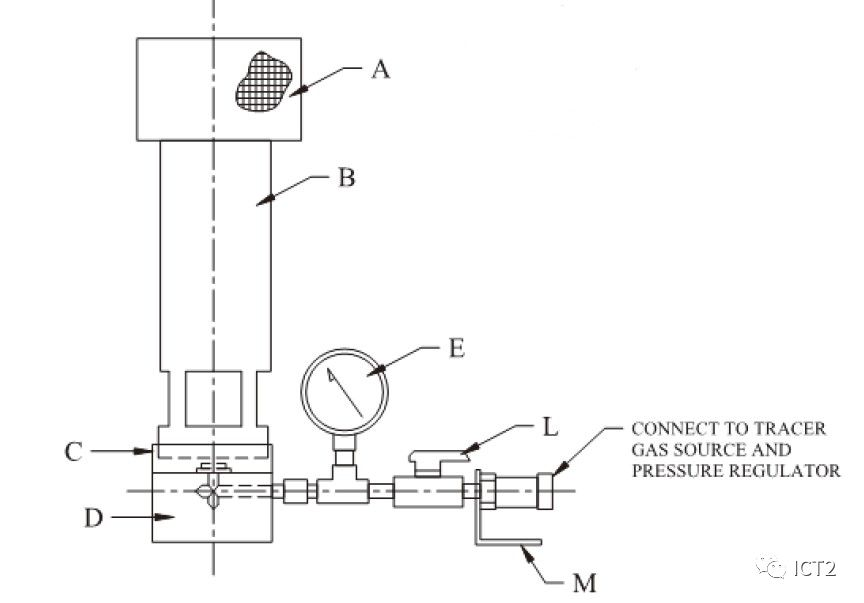

[gas releaser]

Standard drawings are given. Refer to ASHRAE 110-2016 figure 4.1-4.6

SF6 releaser

[SF6 analyzer]

The instrument should be specific for tracer gas analysis; The range of the analyzer shall be at least 0.01-20 ppm; The instrument data output can be connected to the data recorder, and the data output frequency is at least 1 data per second. The inner diameter of the sampling port of the analyzer shall be less than 12mm. The analyzer needs to be calibrated before and after use.

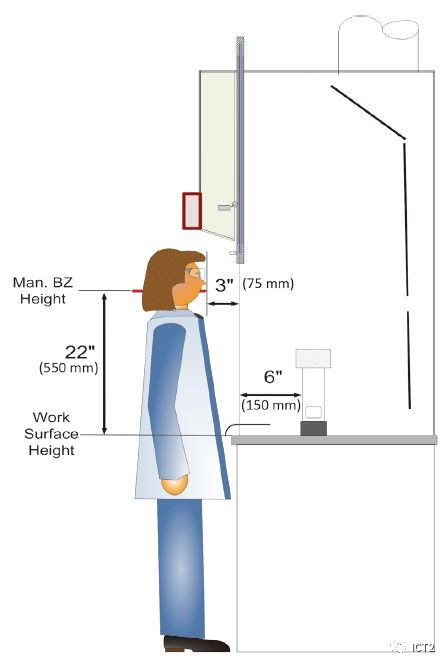

[dummy]

The dummy's shoulder width is 17 ± 2 inches (430±50 mm); The dummy's arms shall be sagged on both sides; The appearance of the dummy needs to have human characteristics and wear laboratory specific decorations.

After the above conditions are met, we can conduct tracer gas test.

A. Tracer gas test

The first test is the tracer gas test. Place the releaser and dummy at the left, middle and right positions respectively. The sampling port of SF6 tracer gas analyzer is located at the mouth. The tracer gas is released for 5 minutes of test and data recording.

With the help of software, this part of the test mainly collects SF6 detection data at three positions on the left, middle and right for 5 minutes.

Dummy and release locations

Dummy and SF6 release locations: left, center, right

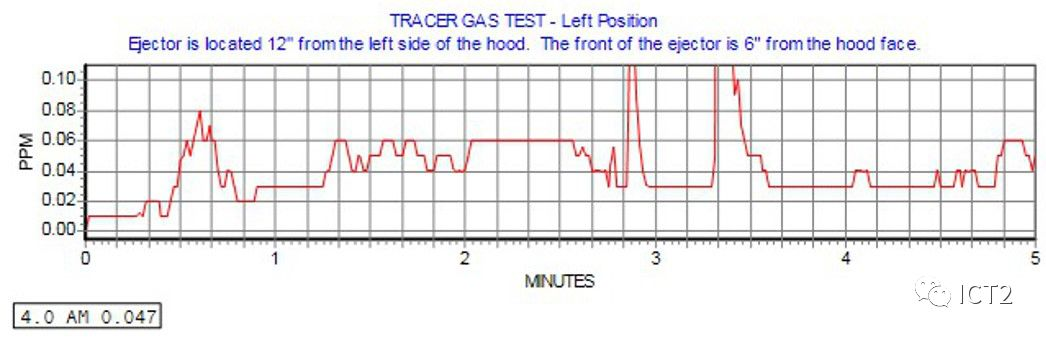

SF6 test results with the release and dummy on the left

*This screenshot comes from ASHRAE 110 performance test software - ALC collegedale

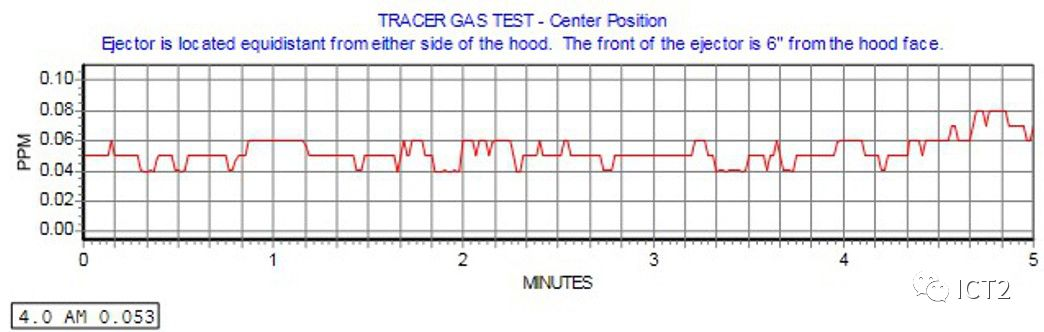

SF6 test results with releaser and dummy in the middle

*This screenshot comes from ASHRAE 110 performance test software - ALC collegedale

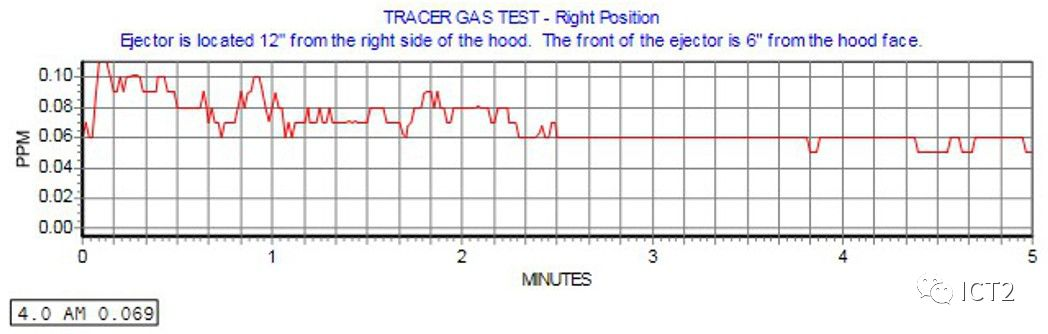

SF6 test results with the release and dummy on the right

*This screenshot comes from ASHRAE 110 performance test software - ALC collegedale

It is worth mentioning that the European EN 14175 test specification believes that the dummy is not necessary because there are differences in human body shape, and the dummy model cannot represent the body shape of all people.

However, according to ashrae110, the dummy is placed to reflect whether the eddy current formed by the operator and the area in front of the fume hood can affect the control performance of the fume hood on pollutants when someone is operating in front of the fume hood.

B. Peripheral sweep test

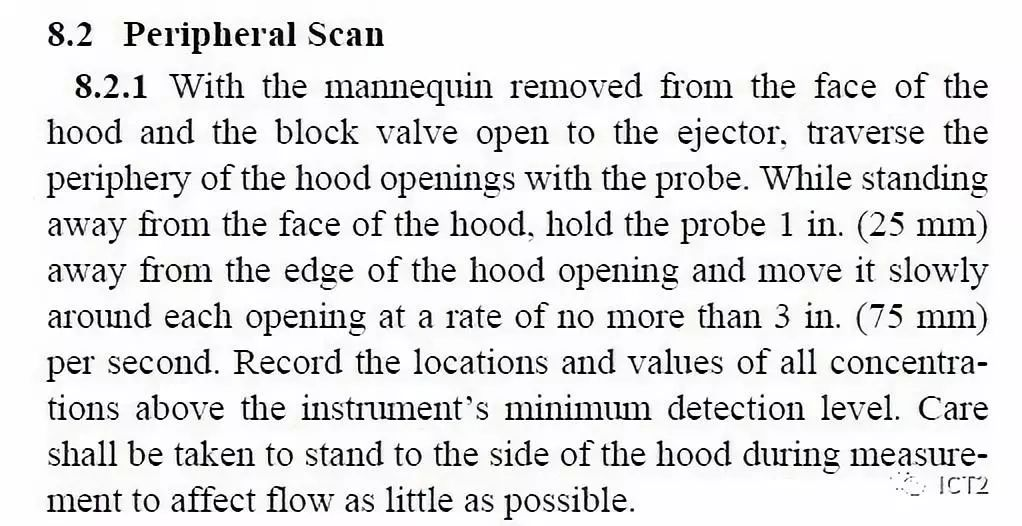

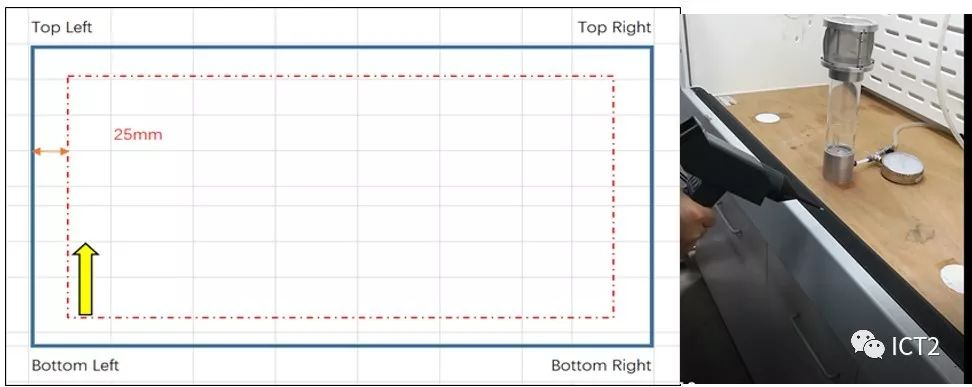

The second test for tracer gas analysis is the peripheral sweep test. The SF6 releaser is placed in the middle position (the edge is 150mm away from the regulating door surface), the regulating door is at the design height, the SF6 release rate is 30psi, 4.0 LPM. The handheld SF6 analyzer shall circle around the window sash at a uniform speed, the probe shall be 25mm away from the edge, and the moving speed shall not exceed 75 mm / s.

Ashrae110-2016 description of peripheral scanning

Schematic diagram of peripheral scanning detection

Similarly, we collect these test data through professional software.

SF6 peripheral scan test results with releaser and dummy in the middle

*This screenshot comes from ASHRAE 110 performance test software - ALC collegedale

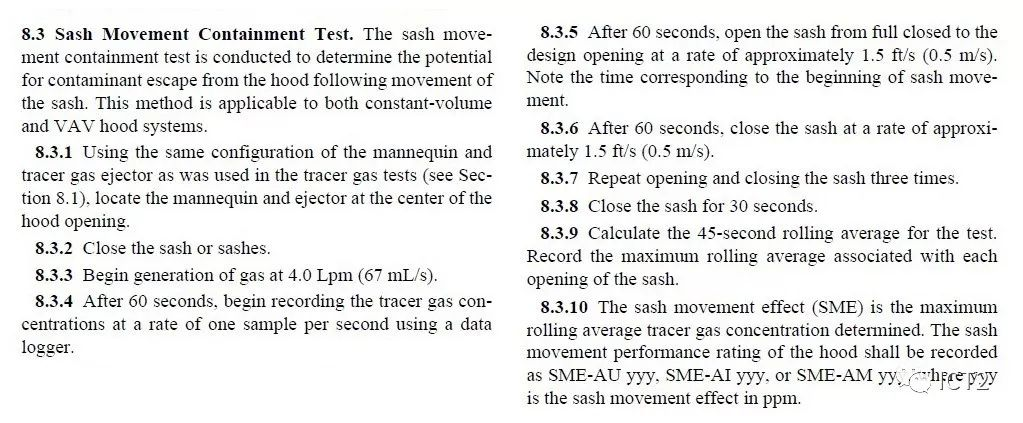

C. Control performance test of moving pollutants of regulating valve

The third test of tracer gas analysis is the pollutant control performance test of regulating gate movement.

Place the SF6 releaser and manikin to the test position; Adjust SF6 release air pressure, 4.0lpm (67ml / s) / 30psi; Release SF6 gas in advance and close the regulating valve for 60s; Start program testing; Close the regulating valve for 60s, then open it to the design working height for 60s, and repeat it for 3 times; Close for 30s, and then end the test.

Control performance test of moving pollutants of regulating valve

Similarly, we collect these test data through professional software.

Test results of moving pollutant control performance of SF6 regulating door with releaser and dummy in the middle

*This screenshot comes from ASHRAE 110 performance test software - ALC collegedale

4 Some opinions and suggestions on testing

ASHRAE 110 is the most common and popular test method at present. It contains test methods with high feasibility and good accuracy. Through these test methods, the performance of fume hood can be objectively evaluated.

The whole test process is not complicated, and the test method is more feasible than en14175. In particular, surface wind speed test and tracer gas test.

As a visual test method, smoke test has the main advantage of being intuitive, but its disadvantage is that the description of the results is subjective. In the whole test process, the selection of smoke generator may directly affect the test results, especially the large smoke test. The main reason is that the large smoke generator generally produces a large amount of smoke. At the exit, the smoke is in the spray state. In this test, large smoke should be avoided from being directly injected into the fume hood as far as possible, but should be released slowly to allow the fume hood to naturally eliminate / inhale these fumes.

For the surface wind speed test, if it is not well designed in the test process (supporting hardware and software), many factors will affect the test results. Face wind speed test needs to test the wind speed of the whole face of the opening of the fume hood. According to the provisions of the standard, the whole face often needs to collect many data points. At present, most manufacturers or testers use hand-held anemometer for detection. The accuracy and stability of hand-held anemometer detection and acquisition position are not easy to control, the reading is difficult to record, and the efficiency is not high. In fact, the hardware and software owned by our team can solve this problem well. We can use the anemometer sensor to fix the anemometer on the iron frame platform, automatically generate the coordinate position of the detection surface according to the software, and then collect the wind speed at these sites through the software. The whole process is completed automatically, the sampling points are accurate and the data read is objective.

For tracer gas testing, the whole process is not very complex. ASHRAE 110 has strict requirements for SF6 analyzer, with an accuracy of 0.01ppm. In fact, there are not many SF6 analyzers on the market. According to the author, tracer gas detector Q200 and Miran are popular at present. According to the selection of equipment by experts in the whole industry, we recommend d-industrialq200 (formerly produced by uson in the United States) as a tracer gas analyzer. The SF6 analyzer with high precision and fast response time has become the most critical part of this test 1,3.

5 References

1. https://www.flowsciences.com/two-well-known-fume-hood-containment-tests-ashrae-110-en14175-a-comparison/

2. Comparison and analysis of testing methods from different standards of fume hood in laboratory Li Siwei, Liu Dong, Li Si Wei, Liu Dong - building thermal energy ventilation and air conditioning, issue 3, 2010

3. https://uson-q200.com/q200-vs-miran/