Fume Hood Accident Emergency White Paper - Fume Hood on Fire, What Should You Do?

Date: 2022-01-18 Source: RUANQI Classification: Resources

Abstract

There's a fire in your fume hood. What should you do? Should you take it out? Should you run? Should you turn off the ventilator fan? Should you activate the building fire alarm? Wait a minute! You're on fire????

Few people answer these questions. Policies are actually different and responsibilities are sometimes unclear. This white paper examines all these issues in as clear and direct a manner as possible. One thing is clear: these problems need to be solved carefully before the fire starts.

Historical review

UCLA had a tragic security incident in 2008. A fire in a laboratory fume hood killed Sheri Sanji, a research assistant. Any laboratory safety accident, including fire, can be prevented. Fire is a publicly visible sign of poor laboratory safety. Researchers involved in research should take responsibility for their own safety. Fire is an accident in a fume hood, and many other unfortunate events may occur in such a controlled area.

Michael Wright [1] correctly analyzes the security perspective of this tragedy: "our own (Security) investigation is about causality and prevention, not guilt. We believe in accountability, and we support appropriate civil and criminal penalties - as I think they are here (UCLA) 。 But this is not our goal. The real problem is how to prevent this tragedy in the future. From what I have seen, academic laboratories have some solutions. I am not aware of any industrial laboratory director claiming that he or she is not responsible for safety. PI (chief investigator) is also responsible. We will not make progress without recognition. "

Unfortunately, many laboratories do not effectively organize the collection of safety data, let alone improve adverse conditions.

Chemical fume hood accidents are more common in high school, college and university chemical laboratories than in commercial laboratories [2].

A study by Dow, DuPont and Corning cited an OSHA report, which concluded that a university researcher was 11 times more likely to be injured than a commercial laboratory researcher. The reason is related to the cultural differences between how educational and commercial laboratories operate. Safety is ranked second after academic research objectives, and only countermeasures are considered after problems arise.

When Sangji injected tert butyl lithium into the fume hood of the UCLA laboratory, the chemical burned and his clothes caught fire.

John K. Borchardt confirmed the differences between academic and commercial laboratory settings and their respective safety records in laboratory fires and accidents in 2013 [3].

"Industrial and government laboratories usually have a good safety record based on personnel training, safety inspection and equipment maintenance. However, the frequency of accidents in academic research laboratories is more than ten times that in industrial laboratories."

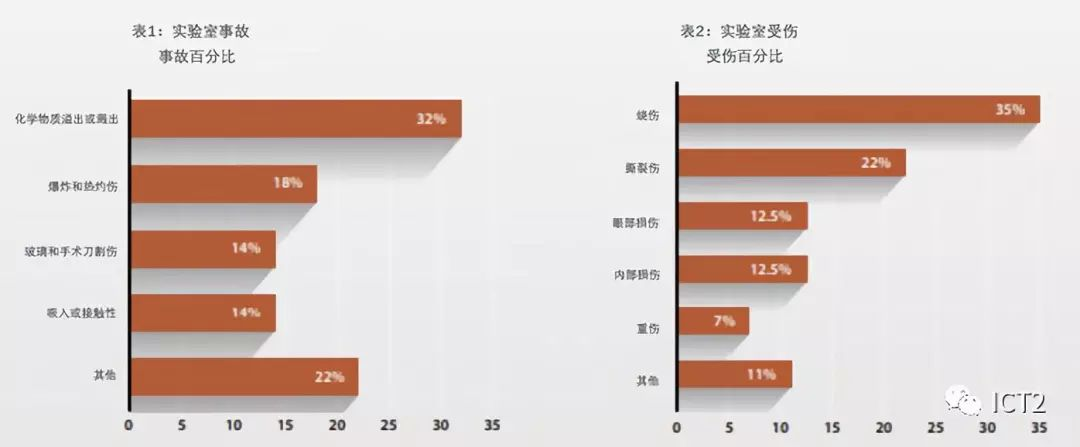

The following is the statistical table of various accidents in the laboratory:

Table 1 shows the types of laboratory accidents reported and their frequency. Explosion and thermal burns are the second most common types of accidents, including injuries caused by exposure to extreme high temperatures, such as burners or hot water.

Table 2 shows the types of injuries caused by these laboratory accidents. Burns and tears together account for more than half of all reported injuries.

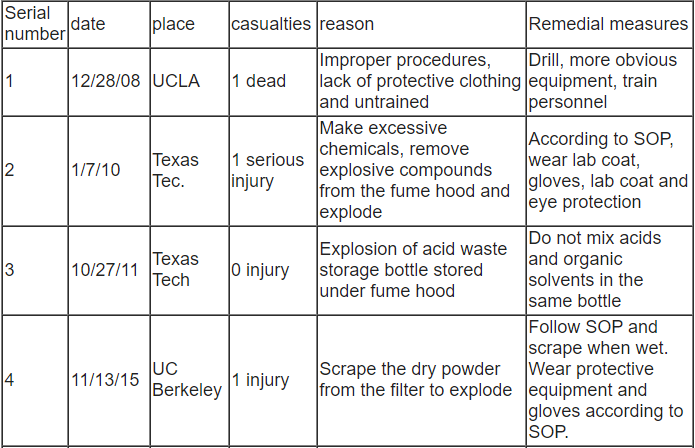

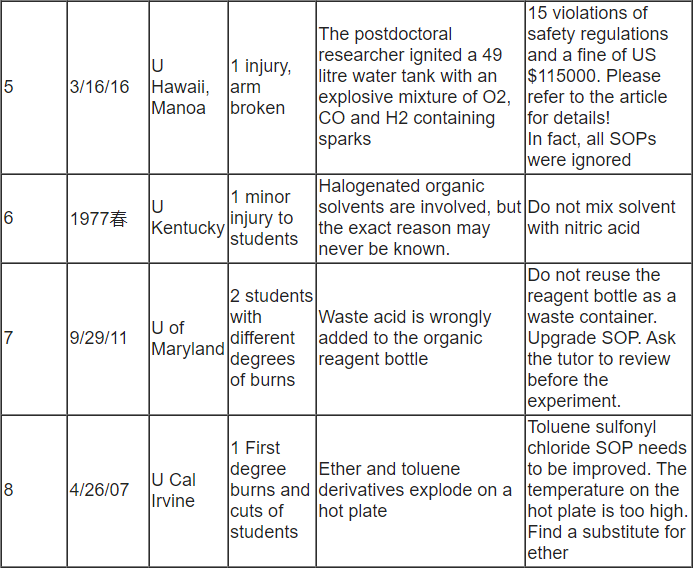

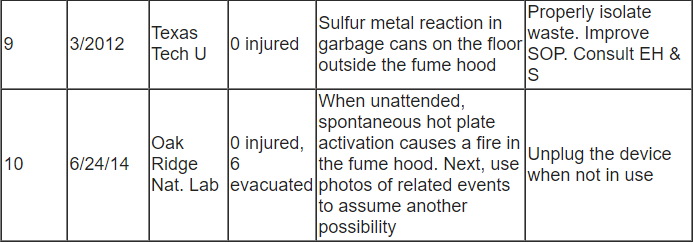

The main percentage of burns and tears in laboratory accidents is significant. Burns and tears are typical in fume hood fires. We can see this from the ten examples cited in the following chart:

Fume hood fire and explosion cases:

Is it possible to use a vacuum pump for several hours to maintain vacuum?

Information induction

1. Fume hood fire is an important problem, which mainly occurs in Colleges and universities and academic research institutions.

2. According to the post accident analysis, the causes of the accident include:

1) Little or no training of laboratory personnel to operate critical research and safety equipment;

2) Little is known about the nature of the chemicals involved;

3) Unreasonable formula or no SOP;

4) No peer (or supervisor) reviewed the proposed procedure;

5) Little is known about the required yield or separation procedures;

6) Inadequate or non-existent in laboratory supervision of students / researchers;

7) Poor laboratory waste monitoring and disposal;

8) Poor laboratory attendance records have blurred accountability;

9) Failure to react the material in the enclosure area of the fume hood;

10) Failure to properly remove the discarded chemical waste from the fume hood or bottom cabinet;

11) Failure to implement safety procedure changes after any specific accident.

Three of the ten accidents in the chart are similar, all occurred in the same organization in three calendar years.

3. Finally, we need to step back and ask four questions before completing any procedure:

1) What the hell are we doing?

2) How did we do it? Can the experiment be completed in a short time, or do you need several phased meetings?

3) What could go wrong?

4) Where are the safety facilities?

Fire extinguishers: they shall be regularly inspected and distributed to the work area according to the fire rating (e.g. a, B, C, D, etc.); Fire blanket; Shower; Fire Alarm; Main power switch and gas cut-off; Exit: it shall always be unlocked and passable;

Returning to the questions raised in the summary, you cannot answer any questions without a security plan similar to the one outlined above.

Summary answer

1) What should you do? Should you take it out?

These problems are solved in the list in the previous section. If a clear list of materials and understandable procedures have been established, many difficulties have been identified and foreseen, including whether extinguishing the fire itself is a good idea.

2) Should you run?

You should probably go to some or all of the items in the list, depending on the contingencies considered during the experimental planning phase.

3) Should you turn off the ventilator fan?

Fire and facility piping practices in different parts of the United States affect the answer to this question. If pipe smoke or heat is detected, some areas need to automatically disable the fume hood exhaust fan. In many other places, local regulations require pipes to be insulated and fans to remain operational during smoke and heat testing. Checking mechanical personnel at your factory will help determine the procedures used in a given facility.

4) Should you activate the building fire alarm?

Understand the fire alarm activation policy, but in the case of a laboratory fire, the answer to this question is usually yes.

5) Wait a minute! You're on fire????

Here, we really need to step back. Any experiment with fire risk should not be completed alone. The use of fire blankets or other personal protection usually requires two people to be effective. The above-mentioned death occurred when other personnel in the same laboratory were engaged in other projects (e.g. UCLA, the first line above). These persons were not informed of the nature of the disaster reservation procedure and were predictably ineffective in emergency situations.

Quote

1. Michael Wright, Director SHE, UnitedSteelworkers 10/5/2018, American Chemical Society CHAS web conference

2. Jon Rvans, Royal Society ofChemistry, Safety First?, 2014, https://www.chemistryworld.com/features/safety-first/7413.article

3. Running Your Labs Like a Business, JohnBorchardt, 2008, Lab Manager Magazine,

https://www.labmanager.com/business-management/2008/07/running-your-lab-like-a-business#.XBkYj1xKiM9

4. SUPPLIMENTAL: EduRiskTM provideseducation-specific risk management resources to colleges and schools, and is abenefit of membership with United Educators (UE) Insurance, 2014,

https://edurisksolutions.org/WorkArea/DownloasAsset.aspx?id=1894…135

5. University of Kentucky Fire (Chart,Item 6)