Real Definition of High Performance Fume Hood

Date: 2022-01-19 Source: RUANQI Classification: Resources

High performance fume hood has different meanings in the whole industry. Therefore, the meaning of the term "high performance fume hood" is often misunderstood. With various definitions and industry terms, the term may be very cunning. This article will help you clear your mind.

ASHRAE 110 tests include surface wind speed tests, smoke visualization tests, and tracer gas tests using sulfur hexafluoride and mannequins

The relationship between air and fume hoods

The air passes through the fume hood with the help of a fan to generate a negative pressure environment and protect users from harmful gases. The air travels at a certain speed. Measure the wind speed of the fume hood in the plane of the sliding door, which is called the surface wind speed, in feet per minute (FPM).

The surface wind speed is related to the amount of air passing through the fume hood. The volume of air is called volume flow and is measured in cubic feet per minute (CFM). The more air is drawn through the opening, the faster the air flows. Using a garden hose as an example, you can place your thumb on the opening of the hose to spray water further, because blocking the opening will speed up the water. The amount of water pumped through the hose remains constant. Since water and air are both fluids, the same physics applies. The surface wind speed (FPM) depends on the amount of air passing through the fume hood (CFM) and the size of the opening through which the air passes, including the bypass area.

Face speed setpoint

Different fume hood models will operate at different surface wind speeds. Since not all laboratories require state-of-the-art fume hoods, many manufacturers provide a range of options.

The specific surface wind speed should be selected according to several variables. The surface wind speed is usually determined by the safety officer of the laboratory, not the fume hood manufacturer. The safety officer may say that the use of fume hoods and 18 inch window sashes at 60 feet per minute may increase the surface wind speed due to poor laboratory conditions or the use of hot plates.

Fume hoods put incredible pressure on energy in the laboratory. They expel expensive, temperature controlled air outside, just like blowing out air with windows open all year round. Therefore, if a lower surface velocity can be used, it should be widely used. Lower surface velocity means lower volume flow, which means energy saving.

Speed is not equal to safety

For the required surface wind speed, the standard range is wide, however, it has been proved that faster is not necessarily safer. In fact, many laboratory standards clearly stipulate that high-speed operation (above 150fpm) will actually pose safety risks due to turbulent air. If the laboratory is balanced and follows the general guidelines for operating a constant volume fume hood, a lot of energy can be saved if the operating speed of the fume hood is less than 100 FPM.

The laboratory may be short of air. If it is short of air, the fume hood will not be able to exhaust normally. Ensure that adequate air supply is provided to the laboratory before adding a fume hood or selecting a face wind speed set point. This does not mean that all laboratories can operate fume hoods at speeds as low as 60 ft / min to reduce the pressure on their mechanical systems. The surface wind speed of the fume hood should be analyzed and carefully specified, because there are many benefits of operating at lower surface wind speed, and higher surface wind speed will lead to risks and unnecessary costs.

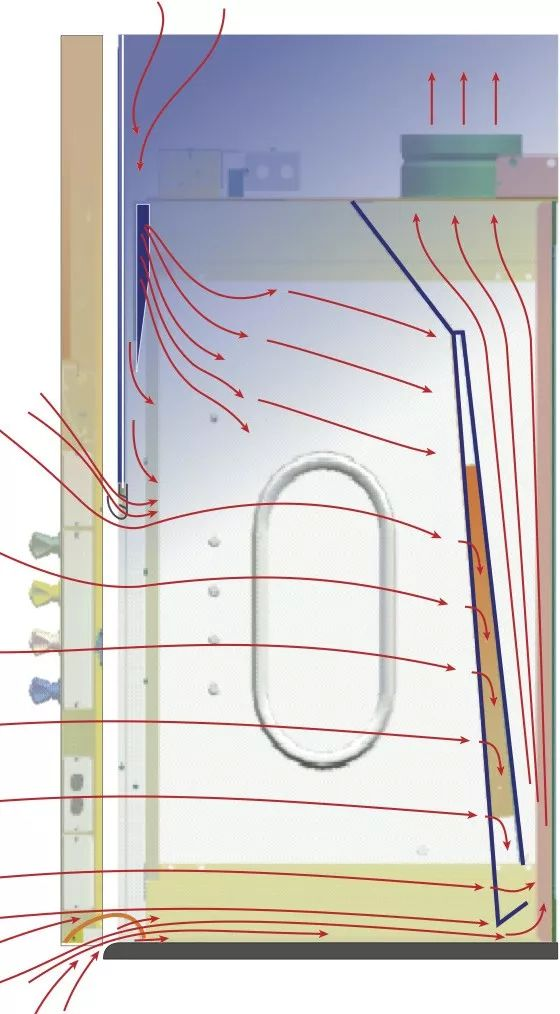

Air flow diagram of high performance fume hood

True high performance fume hood

High performance fume hoods are influenced by many marketing methods and throw out different names in order to attract customers. If fume hoods are called low speed, high efficiency, high energy efficiency or low exhaust volume, they all cite the same thing - some form of nickname "high performance".

The scientific equipment and Furniture Association (Sefa) has defined high efficiency, and any fume hood manufacturing shall meet or exceed one of the above requirements. According to Sefa, high performance fume hoods must pass the following test requirements. ASHRAE 110 test is a three part test to check the sealing performance of the fume hood. The test includes surface wind speed test, smoke visualization test and tracer gas test using sulfur hexafluoride (SF6) and manikin.

According to Sefa, The definition of energy-saving fume hood is as follows: "Low speed laboratory fume hoods are a good design to reduce the amount of exhaust required compared to the volume required for fume hoods of the same size. Through fully open vertical window sashes, the surface wind speed is 100 FPM and provides pollutant control levels equivalent to or better than ASHRAE 110 tracer gas test levels 4.0 am 0.05 and 4.0 AI / Au 0.10, The surface speed is 60 FPM or less. Low speed fume hoods are also called high-performance fume hoods or high-efficiency fume hoods. "

Definition of "4.0 am 0.05"

During the ASHRAE 110 test, SF6 was released at a rate of 4 L / min of "am" - referred to as am -. The acceptable amount of SF6 by the sensors in the manikin shall not be greater than the average value of 0.05 parts per million (PPM).

Definition of "4.0 AI / Au 0.10"

Refers to the release rate of 4 L / min, in the "Ai" or "Au" state - referred to as AI or Au - and the acceptable SF6 amount shall not be greater than the average value of 0.10 ppm by the sensors in the manikin. This test allows a greater amount of SF6 to leak in the AI or Au test because it is carried out in a controlled test laboratory during the AM test. AI and Au tests are carried out in the actual laboratory environment, which may include cross airflow, equipment in the fume hood and suboptimal air supply conditions.

In order to truly achieve high performance, the fume hood must comply with the definition of Sefa. Therefore. It must be tested at a face speed of 60 FPM with a sash opening of at least 25 inches. Some fume hoods are advertised to operate at 60 FPM, but the position of sliding door opening is not listed. The manufacturer must demonstrate that it can operate on a sliding door with an opening of at least 25 inches to obtain a high-performance label.

Historically, most fume hoods have operated at a face wind speed of 100 FPM with sliding doors fully open. For most fume hoods today, this will be full speed and will constitute unnecessary energy consumption in most laboratories. Although there are no exact figures for the ventilation cabinet surface wind speed in each laboratory, the standard state range is usually 60 to 100 FPM. One reason why the standard is so vague about the specified surface wind speed is that the 100fpm of the old style fume hood is very different from that of some new fume hoods.

In addition, depending on the air balance and real-life conditions, these fume hoods will vary from laboratory to laboratory. All these factors need to be considered when planning the laboratory to ensure that the fume hood achieves the best energy saving while still maintaining absolute safety.

Select equipment scientifically

Understand the situation, query the test results and understand the meaning of the test results.

It is very important to ask the manufacturer to provide test reports. Although the test report may represent the results at a surface speed of 40 or 50 FPM, the minimum recommended by the standard is still 60 FPM. The low speed test report is designed to reassure you. They show that there is an additional factor of safety in the fume hood design, even if no standard recommends operations below 60 FPM.

When operating laboratory fume hoods with low surface wind speed, energy saving can be really increased - some high-performance fume hoods can even save energy and return to cost in a very short time. Ask the manufacturer to help you pay attention to the savings in early equipment installation, annual savings and specific installation return on investment.

Since many variables will affect the performance of the fume hood, please determine the size of the fume hood according to the surface wind speed specified by the safety management personnel or the applicable local codes. Determine the acceptable operating range of the fume hood using the performance issued by the manufacturer, and require the test report to back up the performance data.