Fire Protection Problems on Fume Hood Pipes

Date: 2022-01-19 Source: RUANQI Classification: Resources

Abstract

We have studied the accidents in the fume hood, and put forward several questions, which may flash directly into people's minds after the fume hood fire. From the earlier papers cited before and other literature searches, we will study the following questions in the second paper: What structure and installation techniques must be observed when selecting and installing fume hoods to reduce the possibility of fume hood fires spreading to the remaining laboratory space and the whole building? Should the fume hood fan be turned off if the fume hood catches fire? What kind of piping system should be used for exhaust of chemical fume hood? The author reviews these key issues in the rest of this paper.

The key to the question

1) What structures and installation technologies must be observed when selecting and installing fume hoods to reduce the possibility of fume hood fires spreading to the remaining laboratory space and the whole building?

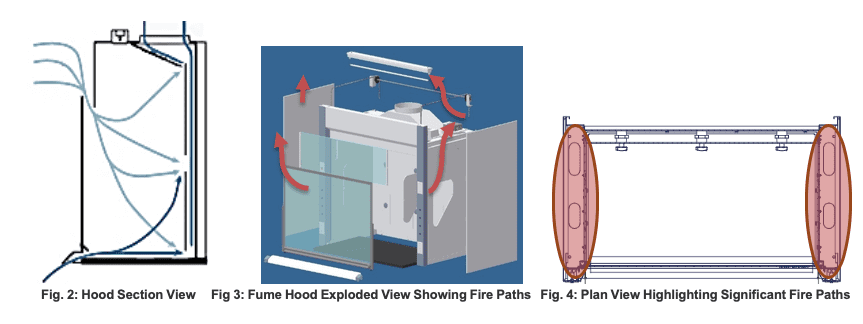

Any fume hood fire will interact with the room where it is located. The ceiling in such a laboratory is the key feature that determines the spread of fire. In this case, the flame may enter the piping system through the fume hood. Let's see how to install such a ceiling and what it should do during a fire.

Suspended ceilings made of fireproof rectangular bricks are usually used in laboratory buildings as a way to stop the fire progress by preventing the flame in the room from rapidly spreading upward and affecting the ceiling of the room, which will accelerate the flame spreading upstairs.

It has been found that such a ceiling must have all appropriate tiles to perform this function. Or the open rectangular space left during maintenance or replacement will destroy the whole protection strategy. Once through such an opening, fire and heat can quickly spread horizontally and upwards, thus directly spreading the flame upstairs.

If the material inside the fume hood is cracked due to heat or cracked pipe access plate, very bad things will happen. The fume hood can guide the fire into the suspended ceiling cavity through the "chimney" formed between the outer shell and the inner material of the fume hood.

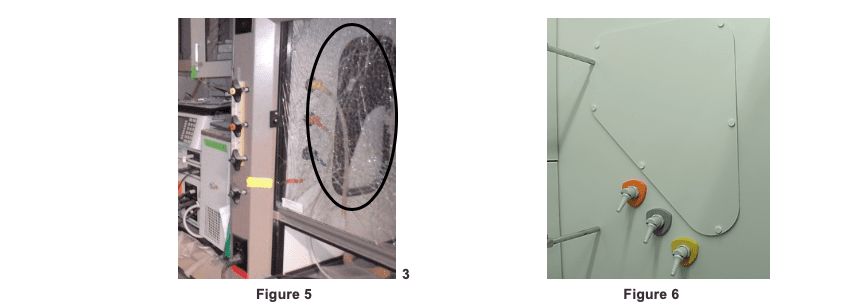

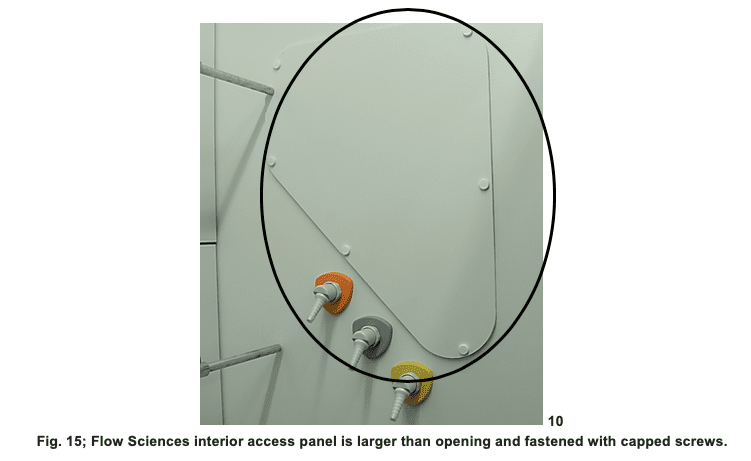

The above shows an actual detached access panel (Figure 5). The panel is smaller than its circular opening, and the gasket is fitted into the notch. In this photo, the gasket has been removed by the explosive force, causing the panel to fall from the opening, thus making the fire path upward. In fig. 6, the screw-in panel larger than the cover opening can resist explosive displacement. In any case, the pipe access panels of the inner fume hood should not be smaller than the openings they cover. Gasket materials used to "seal" such openings should be avoided. More generally, access panels and washers should never be made of melted or possibly deformed materials to prevent them from falling or being squeezed into the cover opening.

Once the flame passes through the inner wall material of the fume hood or enters the opening, it can move upward freely. Fig. 7 shows two fume hoods softened into ceiling; The open gap above the fume hood will make the flame enter the ceiling cavity, which will destroy its effectiveness. A complete ceiling is the preferred building! (Figure 8) The fume hood is obviously separated between the ceiling and the upper structure of the fume hood, and the flame retardant characteristics of the ceiling are retained.

If the fume hood flame spreads into this suspended ceiling cavity, it will move horizontally relatively unimpeded. Because the "walls" of many laboratories end in the suspended ceiling, these areas are usually huge and untidy fire exits.

Section 6.1.1.1 of NFPA 45 requires that sprinkler systems in all new laboratories comply with NFPA 13. NFPA 13. Sprinklers should be installed under such ceilings for complete ceilings. Incomplete ceilings, sometimes called "cloud ceilings", may require the use of sprinklers above and below the ceiling line. The difference here is a bit unclear. Obviously, the area above the ceiling should be properly protected by sprinklers in accordance with NFPA 13 and local regulations.

Francis Branaghan 5 summarized the general fragility of ceiling design as follows: "In the first edition of fire service building construction (1971), I pointed out the basic defects of this system: the loss or failure of a tile exposed the whole building to the fire. The fire engineer of General Services Administration (GSA) told me that GSA had never built this type of building. "

In a word, the ceiling design of the laboratory should not include the" through "opening of the upper structure of the fume hood. The complete ceiling should always be placed above the whole laboratory, including the upper structure of fume hood. Such a complete ceiling will resist the flame entering the painted steel shell from the inner containment area of the fume hood, where they can easily pass through the upper structure of the fume hood like a chimney. Therefore, the contractor should not use the upper structure of fume hood as the fixing point of laboratory ceiling. There is a clearance hole above the fume hood on the hanging ceiling. This situation obviously aggravates the spread of any fume hood fire through the ceiling space.

There is a very noteworthy example to illustrate how the ceiling space can quickly spread the laboratory fire. It happened in 2012 in Tulsa, Oklahoma:

"The historic Barnard school building caught fire around 5 am on September 5th. When firefighters arrived, the building exploded and swayed in the center of Tulsa, and eight firefighters were dispatched to the hospital. After a week-long investigation, officials said that the fire and explosion were caused by "installing vent-related structures in the laboratory area", according to news reports. The reason for the explosion is that the flame in the gap between the ceiling of the chemical laboratory and the floor and corridor of the room has been smoldering. Investigators said that the fire moved northward to the classroom under the corridor floor, and the crawling space below was discharged from the classroom window. When firefighters enter the room to put out the fire and oxygen is introduced into the area, smoke explosion or "countercurrent" will occur.

2) If the fume hood catches fire, should the fume hood fan be turned off or the fire damper be started?

First, we turn to the latest NFPA 45 standard to determine whether the damper should be automatically turned off in the fume hood when there is a fire in the pipeline: 7.5.10.1.1 In the case of balancing or controlling the exhaust system, the control device and shock absorber should be opened in case of failure to ensure the type of continuous ventilation. NFPA 45 explicitly prohibits fume hood fire dampers. In addition, this year, a clause (7.5.10.1.1) was added, stating that the flow control damper added in the exhaust duct of the fume hood for other reasons must be turned on. With regard to closing the exhaust ventilation in case of fire, NFPA 45 section 7.5.11 stipulates that the fire detection and alarm system should not be interlocked to automatically close the exhaust fan in the laboratory.

Although NPPA did not explain why this requirement was put forward so strongly (it should be used in all cases), there are many well-known realities here: Stopping the flow through the fume hood exhaust pipe during a fire will ensure that all combustion by-products will explode back into the laboratory area. (carbon monoxide, aromatic hydrocarbons, soot, others). In a fume hood fire, the exhaust of a functional fume hood will release heat and smoke. In the short term, the exhaust cut-off will increase the temperature in the receiving cavity and damage the structure more quickly. People who escape from the laboratory need fresh air, which will be sucked into the laboratory in proportion to the exhaust gas extracted from it. To some extent, this problem has almost become an academic problem, because fewer and fewer fume hoods use fan switches first. In view of these problems, we come to the conclusion that the fume hood exhaust device should not be turned off in case of fire!

3) What kind of piping system should be used for exhaust of chemical fume hood?

NFPA 45 puts forward this question again, although it is ambiguous:

7.5 Pipeline construction of fume hood and local exhaust system

7.5.1 Pipes from chemical fume hood and local exhaust system should be made entirely of incombustible materials, except for the following situations:

(1) Flexible pipes with flammable structure should be allowed to be used in special local exhaust systems in laboratory working areas. (See 7.5.2)

(2) If in a shaft with closed nonflammable or limited flammable structure, it is allowed to use combustible emissions through non-laboratory areas or laboratory devices (except the laboratory devices it serves). (See 7.5.2)

(3) As described in Chapter 6, if all areas passing by are protected by approved automatic fire extinguishing systems, combustible emissions should be allowed (see 7.5.2).

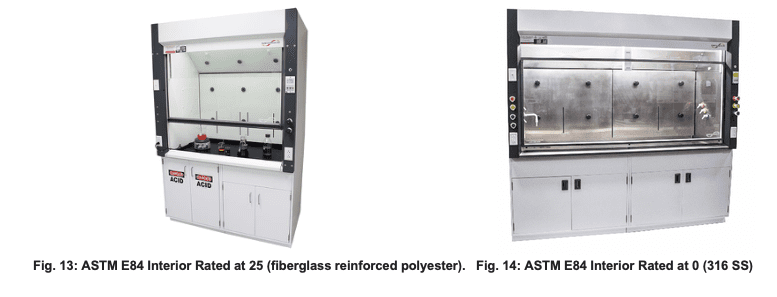

7.5.2 When testing according to ASTME84 Standard Test Method for Surface Combustion Characteristics of Building Materials or ANSI/UL723 Standard for Surface Combustion Characteristics of Building Materials, the flame spread index of combustible pipeline or pipeline lining should be less than or equal to 25, and the test sample should be the minimum thickness used in pipeline or pipeline construction.

8.3.3.2 Pipeline Construction Materials The structural materials of pipelines and containers should be compatible with the materials to be transferred or transported.

Although the interior of fume hood and piping system are limited to flame spread < 25, the piping system must also be compatible with conveying materials (8.3.3.2). If the laboratory designers hope NFPA 45 can give specific help to the pipeline types, they will be very disappointed with the 8.3.3.2 Festival. Especially in large-scale projects with different laboratories, this rather vague part about pipeline compatibility assumes that chemists all do the same thing and have a full range of pipeline types. These assumptions are impossible. Piping systems made of different materials behave differently. The following are examples:

1) Stainless steel piping system is very good, except halogen acid like HCl (one of the most common reagents).

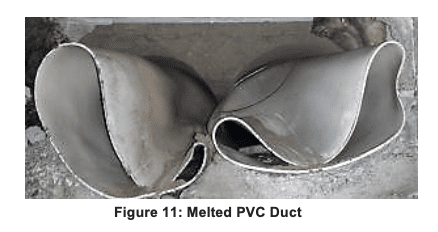

2)PVC piping system is suitable for acid smoke such as HCl(g), but some types will become soft at 250.

3) Galvanized steel pipe system (the cheapest option) may be suitable for milder applications, unless corrosion occurs when the amount of exhausted corrosive agent is greatly increased in some new applications.

How can architects/designers ensure the safety of the building when new chemical projects and tasks change the conventional chemicals to be discharged into the original pipeline in the laboratory building, because the pipeline may no longer meet the requirements of NFPA 45 8.3.3.2 Festival? Because of the above problems, Flow Sciences always asks customers application questions. What is your application? How many reagents are used up every week? Do you consider energy saving by reducing exhaust volume? What are the opportunities for major changes in your application?

Obviously, when manufacturers ask such questions, we will protect ourselves and our customers from receiving the wrong products. The exhaust problem of the whole building is always a bigger problem, which is usually forgotten during building maintenance. With the improvement of VAV and other low-energy technologies, the exhaust gas flow of fume hood process will be further reduced, and the concentration of corrosive exhaust gas will increase. Installation of pipelines for more diluted flue gas concentration may be seriously challenged!

Conclusion

1) From the fire safety point of view, a well-designed fume hood must have a sealed cavity made of ASTM E84 flame spread less than 25.

All internal channel cuts should be covered with lining material and have similar low flame spread. The side wall access panel must be larger than the cut-out and fixed with screws instead of washers, unless the washers will not burn, melt or loosen in case of fire.

Apart from this precaution, the fume hood should never be installed as part of the ceiling support system. The ceiling should be higher than the fume hood and never pass through it!

2) During the fume hood fire event, the fume hood exhaust system should never be turned off. Damper should not be closed. Not automatic, not manual.

NFPA 45 is very clear on this issue. Influence on Laboratory Personnel and Indoor Fire The participation rate of disabling exhaust system is usually worse than that of allowing the system to operate.

3) ASTM E84 flame spread of chemical exhaust pipe is less than 25.

Although any pipe must be compatible with exhausted materials, the facility should record the type of pipe used, so when the application of fume hood changes with time, it can be checked whether the new use is compatible with the existing pipe. When necessary, the non-zero flame spread piping system must adopt the fire shielding described in NFPA 45. Commonly used pipeline materials are stainless steel, PVC and galvanized steel. Each material has its limitations and advantages, which can be reviewed according to the use of laboratory waste gas. In a word, we have seen that the fume hood fire must be seen above and inside the fume hood. The maintenance of fans, piping system and complete ceiling can play a role in preventing serious laboratory fires.

Footnote

1. Fume Hood Fires, Robert Haugen, Flow Sciences White Paper, 8/2018, https://www.flowsciences.com/fume-hood-firessmoke-heat-and-finally-illumination/

2. Making Sense of Laboratory Fire Codes, Richard Palluzi, AIHCE Journal, pp 54-58

3. University of Hawaii Fined $115,000 for lab explosion, C&EN News, Sept 29,2016

4. Overview of the International Mechanical Code, International Code Council, 2018, https://www.iccsafe.org/products-and-services/i-codes/2018-i-codes/imc/

5. https://www.fireengineering.com/articles/print/volume-158/issue-4/departments/the-ol-professor/suspended-ceilings.html, FRANCIS L. BRANNIGAN, SFPE (Fellow), the recipient of Fire Engineering’s first Lifetime Achievement Award, has devoted more than half of his 63-year career to the safety of firefighters in building fires. He is well known as the author of Building Construction for the Fire Service, Third Edition (National Fire Protection Association, 1992) and for his lectures and videotapes. Brannigan is an editorial advisory board member of Fire Engineering.

6. https://www.huffpost.com/entry/chemistry-fire-video-lab-sprinklers_n_3314085

7. Flow Sciences floor mount fume hoods

8. https://publicsafety.tufts.edu/ehs/fire-safety/

9. http://www.expertconstructioninc.com/acoustical.html

10. This is a photo of the Flow Sciences Saf T Flow fume hood sidewall access panel. Other manufacturers emulate this design.