How to Choose VAV Equipment of Fume Hood Correctly?

Date: 2022-01-19 Source: RUANQI Classification: Resources

Foreword

Recently, people are more and more interested in the control system of VAV fume hood [1]. This paper will define this kind of system in the most basic sense. Then, the range of HVAC system affected by fume hood VAV will be explained in detail. Finally, I will make suggestions on the best way to specify such systems, so as to obtain the best overall finished products from all relevant construction suppliers.

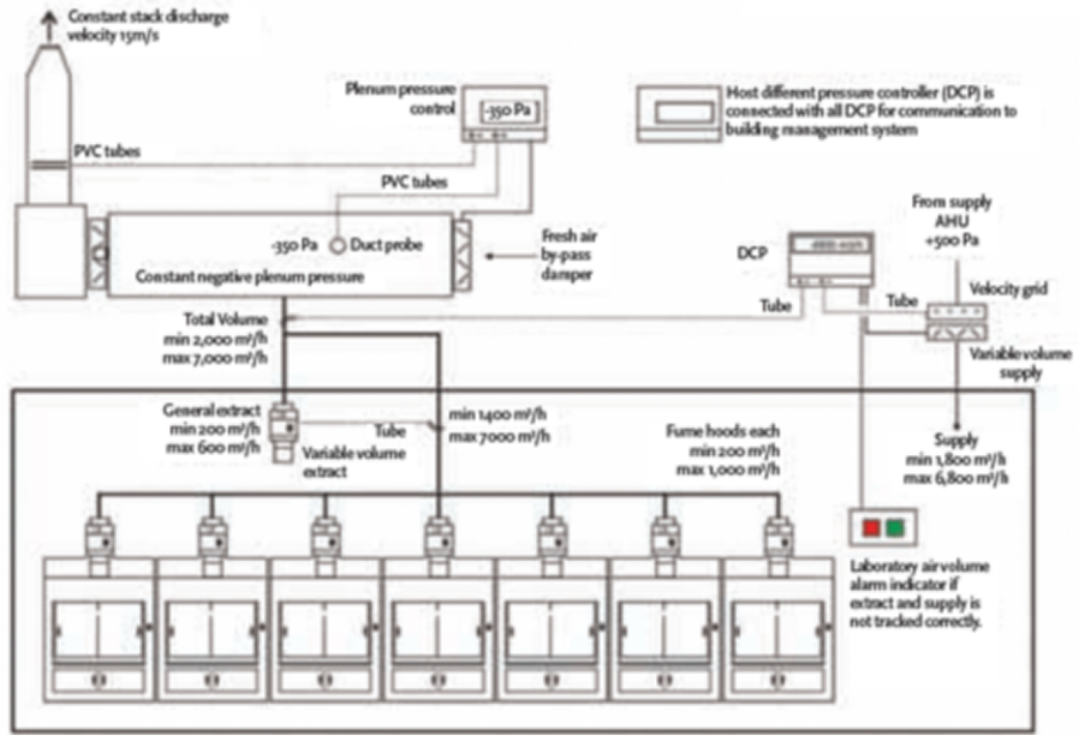

▲ Typical VAV system

( https://www.cibsejournal.com/cpd/modules/2013-10/)

Definition and explanation of VAV system

VAV chemical fume hood changed the amount of indoor air discharged, and kept the surface wind speed at the set level until the lowest sliding door opening. Different VAV fume hoods use different methods to change the exhaust volume. The exhaust damper can be opened or closed according to the position of the sliding door, or the inverter fan can change the RPM of the fan to meet the requirements of air volume. The purpose of reducing the exhaust volume of fume hood (depending on the position of sliding door) is to give laboratory designers the opportunity to exhaust less treated air, at the same time, to maintain an appropriate working face wind speed, save energy costs and promote sustainability.

ASHRAE 110-2016 solved the problem of VAV fume hood in B3.9 in the following ways [2]:

"Although most laboratory fume hoods are installed on CAV system, more and more laboratories use VAV air supply and exhaust system. These VAV systems can reduce the amount of air discharged from the laboratory. It is very important to ensure the correct design, calibration and maintenance of VAV system. VAV system, like all other components of HVAC system, must operate correctly to ensure that the performance of fume hood will not be damaged. "

VAV fume hood is electronically connected to the heating, ventilation and air conditioning system (HVAC) of the laboratory building, so the exhaust air volume of the fume hood and the indoor air supply volume are balanced. In rooms with multiple fume hoods, if the flow balance cannot be achieved, the laboratory may be in a positive or negative pressure state.

The scenario of "unbalanced laboratory" means that the exhaust and air supply are obviously different. The laboratory area with large positive pressure may be potentially dangerous, especially when an accident occurs in the positive pressure laboratory and chemical volatiles are blown out of the laboratory and blown into other key spaces. Most new VAV fume hoods have monitors and/or alarms to warn operators of positive situations that may lead to unsafe pollutant control conditions [2]. The boundary level of unacceptable positive pressure in the laboratory is usually set at 0.1 "W.G. (about 0.00036 pounds per square inch [psi]) [3]. Although it can be measured, this number is a challenge for accurate measurement, and not knowing this value will make the laboratory personnel without any alarm.

Laboratory pressure difference is only one example of why it is necessary to accurately measure the flow in VAV system. The elements shown in the following laboratory schematic diagram must be accurately measured and adjusted to ensure a safe and powerful exhaust system of VAV fume hood [4]:

▲ Figure 1: Typical VAV components of laboratory fume hood

( http://ateam.bl.gov/Design-Guide/DGHtm/vavsystems.htm )

The four boxes in Figure 1 highlight four key elements of any VAV system:

1) The red box shows the fume hood and its VAV valve.

2) The blue box shows the VAV valve of room exhaust. In some cases, this valve is not included, because the indoor exhaust is generated by the fume hood.

3) The green box is the room make-up air valve, room differential pressure sensor and supply pipe.

4) The purple box (rounded corner) is the control module.

5) It should be added that the system shown uses valves instead of VFD (variable frequency drive) multi-rpm exhaust/supply fans. VFD designs are used less frequently because their response time can't keep up with the fast and unpredictable sliding door movement.

Assuming that the design of 1-3 in the box is correct and the exhaust response time is in the range of 1-2 seconds, then the purple box will become a real challenge. The pressure control module must change the exhaust volume and supply air to provide the design surface wind speed to the fume hood, and at the same time increase or decrease the indoor supplemental air to make the indoor static pressure difference slightly negative. Do not mistakenly discharge a large amount of unexpected toxic substances inside the laboratory under the positive pressure of the laboratory and infiltrate into the adjacent laboratories.

In the past 30 years, the application of VAV technology has been increasing, and various operational problems have been recorded in VAV system of fume hood, similar to that shown in Figure 1:

1) The components in 1)VAV system must adjust the lag time of sensors/valves, so that the system will not degenerate to the state that the laboratory circulates between high pressure and low pressure.

2) In order to achieve stability, the response time of each element must be fast enough to ensure that the change of sliding door position will quickly produce a stable and balanced system, and the surface wind speed of fume hood is acceptable.

3) In view of the fact that the defining control element of any VAV system is the actual ventilation hood surface wind speed reached at a certain sliding door position, the surface wind speed measurement technology should not be measured by inference without evidence that this inference is effective under laboratory conditions. The most reasonable criticism of VAV is that some related variables that are crucial to operator safety and exhaust/air supply stability are not often directly measured. These variables may include:

A) surface wind speed of fume hood

B) Exhaust CFM of fume hood

C) total room exhaust

D) Total number of rooms

E) room static pressure difference

Despite the problems discussed above, VAV fume hood is already a fact, and is increasingly becoming a way of laboratory design in the 21st century [5,6]. Therefore, all companies that manufacture fume hoods must provide efficient VAV fume hoods, and be prepared to compete in the open market to sell them and effectively install them into HVAC systems provided by others to the site.

From the perspective of our products (fume hoods), this market reality needs to establish clear performance specifications and subcontractor responsibilities before specifying, purchasing and dividing VAV system elements. Architects, mechanical engineers and HVAC contractors should be responsible for explaining the responsibilities of each subcontractor in realizing functional, stable and safe fume hood exhaust system. The system must go far beyond the set of independently tested components. In such a system, at least three key elements must work together:

1) Efficient fume hood, with strong sealing performance and controllable surface wind speed [7].

2) The location of fresh air and exhaust air is correct to ensure the stability of indoor air flow.

3) An automatic control system can maintain each laboratory at a proper negative pressure, regardless of the position of the sliding door of the fume hood.

Architects, mechanical engineers and HVAC contractors should be responsible for explaining the responsibilities of each subcontractor in realizing functional, stable and safe fume hood exhaust system.

Actual requirements of specific VAV exhaust system

▲ System debugging and calibration is very important for safe use of VAV fume hood

Researchers put forward the following suggestions for VAV system of designated fume hood. These steps are applicable to all subcontractors, who are jointly responsible for providing effective laboratory ventilation system:

1) the primary task of any fume hood VAV system must be safety. In the past 30 years, the author used ASHRAE 110 standard, which was updated regularly, to participate in the formulation of fume hood pollutant control standard. The latest version of the fume hood pollutant control standard is ASHRAE 110-2016 [8]. In particular, this standard specifies the method of evaluating VAV system (Sections 6.2 and 6.3). Although ASHRAE test failed the pass/fail standard, ANSI/AIHA Z 9.5-2012 used ASHRAE 110 program to set the pass/fail AM test standard to 0.05 ppm [9].

This failed limit has caused some controversy. Jerry Konigsberg, a laboratory planner, thinks the number of passing failures is too large, while Gregory Muth, a consultant and laboratory designer, thinks it is too small. Mr. Muth pointed out that many applications of fume hood sealing should not require the control level standard of 0.05 PPM, but should be "higher" [10].

It is problematic to make a specific pollutant control level higher. First of all, if the application of fume hood determines the setting of pollutant control level, what will happen when the application of fume hood changes? Secondly, because the design surface wind speed is reduced, no fume hood can smoothly transition from a lower control value to a higher control value. On the contrary, the pollutant control level suddenly fails at some time, and a new performance level thousands of times larger is produced. Like concrete bridge supports, if we set the acceptable test level just above the failure point, we will also take risks.

2) Although fume hood is considered as "furniture" in traditional parameter format, in modern VAV parameters, its performance must be evaluated as a part of larger laboratory ventilation picture. In order to evaluate the protective performance of the fume hood, an appropriate air circulation environment must be established, and then the fume hood is verified by ASHRAE 110 pollutant control test. Many improperly designed or uncalibrated components of VAV system may cause serious system pollutant control problems in field debugging and testing. This usually means that the fume hood can't work because of other parts in the exhaust system, and other methods are needed to determine and correct the reasons for poor performance.

▲ASHRAE 110-2016 fume hood pollutant control test, ICT2 test laboratory

For example, if the exhaust fan does not work, the fume hood will not work. If the sensor can't measure the flow parameters correctly, the fume hood may not work properly. Before evaluating the pollutant control performance, each VAV component must be correctly synchronized with all other input parameters of the VAV pollutant control system.

3) Finally, the whole HVAC contract should include the work required to ensure the system stability and fume hood pollution control. System debugging is a team sport. Any team needs a leader. All parts of HVAC problems should work normally. A poor laboratory designer who has not considered the overall structure of HVAC may not know how it should work, and when new performance problems are found in building commissioning, he will not be able to supervise and determine the repair scheme.

▲ Commissioning before laboratory delivery, the commissioning project of ICT2 in India.

This stability evaluation should start from the local control box and gradually enter every corner of the system. Understanding system dynamics is very important. All in all, the laboratory VAV fume hood must be used together with other important components of the fume hood exhaust system. Valves, exhaust fans, sensors, constant temperature control and BMS control the laboratory pressure are all very important for the safe production of the laboratory exhaust system. If "keeping the system running" is not a unilateral contractual responsibility, the HVAC system will easily have "migraine" at the end of the laboratory project.

cite

1. R&D Magazine, 10/21/2009, The Great Fume Hood Debate, Paul Livingstone

2. Dale T. Hitchings, PE, CIH, Laboratory Space Pressurization Control Systems, 2001, http://www.safelab.com/FACT_SHEETS/Pressure.pdf

3. ANSI/ASHRAE Standard 110-2016, Methods of Testing Performance of Laboratory Fume Hoods, March 31, 2016,

4. Wikipedia, Fume Hood, Variable Air Volume.

5. http://ateam.lbl.gov/Design-Guide/DGHtm/vavsystems.htm

6. Greg Muth, Laboratory Design News, Sustainable Lab, 10/12/2015, https://www.labdesignnews.com/article/2015/10/fume-hoods-lab-design

7. Gordon Sharp and Others, R&D Magazine, 2010, Airing Out Laboratory HVAC, pp1-3, http://www.aircuity.com/wp-content/uploads/RD-Magazine_Airing-Our-Lab-HVAC_2010_08_Eprint.pdf

8. ASHRAE 110-2016 and ANSI/AIHA Z9.5 together establish testable minimum safety standards.

9. ANSI-AIHA Z 9.5, Section2.4.1, explanation column.

10. R&D Magazine, 10/12/2015, Fume Hoods in Lab Design, Hock, Lindsay, p 1 of 7, https://www.rdmag.com/article/2015/10/fume-hoods-lab-design