What Are the Types of Bio-cabinets?

Date: 2022-01-19 Source: RUANQI Classification: Resources

There are many categories of biosafety cabinets. What are they and what are their differences?

The category of biological safety cabinet is a category that describes the working mode and protection contents of the safety cabinet. These "categories" are Class I, Class II and Class III respectively.

CLASS I

Class I is defined as the biosafety cabinet for personnel and environmental protection. Class I bio-safety cabinet does not provide product anti-pollution protection, which severely limits its application. They stay away from the operator by using the non-circulating airflow. The ventilation mode of Class I biosafety cabinets is similar to that of fume hoods, and they are equipped with HEPA filters at the exhaust ports.

CLASS II

CLASS II is defined as the biosafety cabinet for personnel, products and environmental protection, which is used for microbial work or sterile pharmaceutical preparation. Class II biosafety cabinet is designed with an open front, with inward airflow (personnel protection), downward HEPA filtration laminar flow (product protection) and HEPA filtration waste gas (environmental protection). This kind of safety cabinet is further distinguished according to the structure, air flow and exhaust system type. Include types A1, A2, B1, B2 and C1. They require that all pipes and ventilation rooms polluted by biology be under negative pressure or blocked by negative pressure pipes and ventilation rooms. B2-type safety cabinet goes further, requiring all biologically polluted pipes and ventilation rooms to be under negative pressure or blocked by negative pressure pipes and ventilation rooms for direct exhaust.

TYPE A1

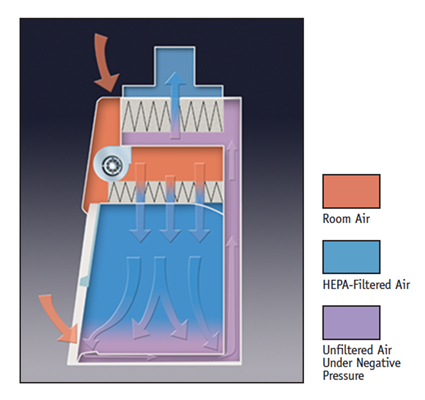

Class II, type A1 safety cabinet must keep the minimum average inflow speed of 75 fpm(0.375 m/s) when passing through the opening of sliding door. The downward airflow filtered by the high efficiency air filter is mixed with the circulating air. All or all of the air filtered by the high efficiency air filter flows back to the laboratory. They are suitable for the use of biological agents that do not contain volatile toxic chemicals and volatile radionuclides, but they are not suitable for the compounding of sterile dangerous drugs. May have positive pressure piping system.

TYPE A2

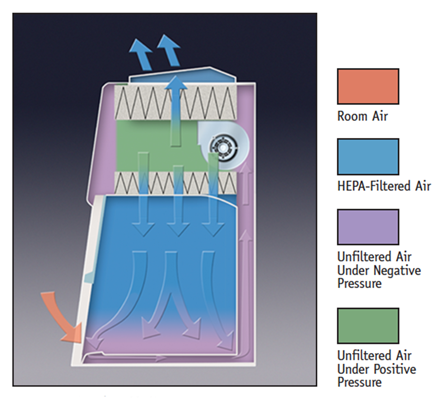

Class II, type A2 safety cabinet must keep the minimum average inflow speed of 100 fpm(0.5 m/s) when passing through the opening of sliding door. Like A1 type safety cabinet, the downward airflow filtered by high efficiency air filter is mixed with circulating air. Some or all of the air filtered by the high efficiency air filter may flow back to the laboratory. A2 type safety cabinet with top connection is safe for work involving biological agents treated with a small amount of hazardous chemicals. They can also be used together with tracer amounts of radionuclides, and if they are recycled in the downstream air, they will not interfere with the work.

TYPE B1

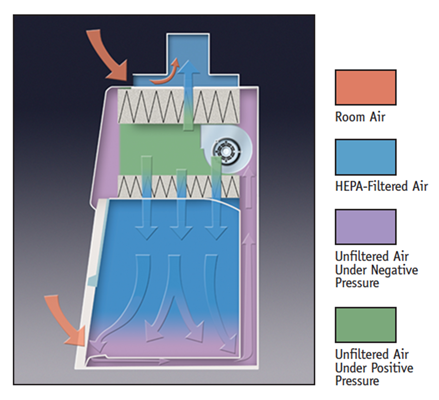

Class II, type B1 safety cabinet must keep the minimum average inflow speed of 100 fpm when passing through the opening of sliding door. They have downstream air filtered by HEPA, most of which is composed of unpolluted recycled inlet air, and most of the polluted downstream air is discharged through special pipes, which are discharged outside after passing through HEPA filters. Similar to A2-type safety cabinet, B1-type cabinet is also safe for work involving reagents treated with trace toxic chemicals and radionuclides, provided that the recirculation of chemical reagents or radionuclides in downstream air will not interfere with work. Unlike A2 type cabinet, B1 type cabinet is also suitable for operations involving trace toxic chemicals and trace radionuclides. These operations are auxiliary means of microbiology application, as long as the work is carried out at the rear part of the cabinet's direct exhaust (this part is unmarked, so it changes constantly with the load of HEPA filter of air flow mode random cabinet.

TYPE B2

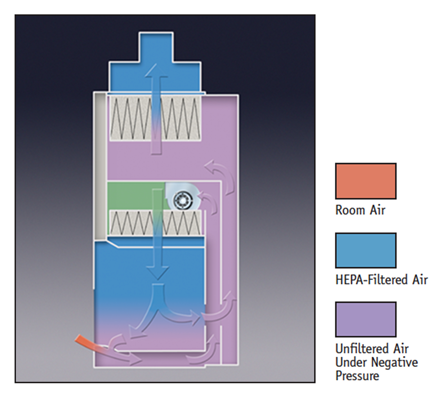

Class II, type B2 safety cabinets must maintain the minimum average inflow speed of 100fpm when passing through the opening of sliding door. They have HEPA-filtered downward air or external air sucked from the laboratory (not recirculated from the exhaust gas of the safety cabinet), and all inflow and downward air is discharged to the atmosphere after being filtered by the HEPA filter without recirculation in the safety cabinet or returning to the laboratory. Therefore, they are sometimes called 100% exhaust cabinets or total exhaust cabinets. B2-type safety cabinet is suitable for work involving harmful chemicals and radionuclide-treated microbial preparations as the auxiliary of microbial application.

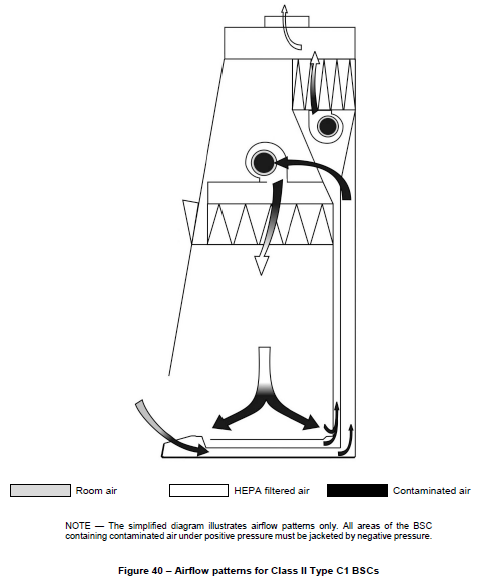

TYPE C1

Class II, type C1 safety cabinet must maintain the minimum average inflow speed of 105fpm when passing through its sliding door opening. C1-type safety cabinets are unique in that they can be used as A-type cabinets in circulation mode or B-type cabinets in exhaust. By connecting or disconnecting the exhaust port and re-certifying, C1 safety cabinet can be quickly changed from one mode to another. C1 also has a marked working area with a clearly defined storage space and a dedicated direct exhaust device, which can be used together with harmful vapor or radionuclide.

CLASS III

Class III biosafety cabinet is a completely closed ventilated cabinet with a sealed structure and rubber gloves for operation in the cabinet. Class III safety cabinet is also called glove box. There is a transfer room in the cabinet, which can sterilize the materials before they leave the glove box. Keep the cabinet under negative pressure, and the supplied air is sucked through HEPA filter. The exhausted air is treated by double HEPA filtration or HEPA filtration and incineration. Class III safety cabinet can provide safety protection for the work required by biosafety levels 1, 2, 3 and 4.